The side business of Henry Ford Charcoal almost never happened. After two failed attempts at establishing an auto company, Henry Ford founded the Ford Motor Company on June 16, 1903. It was only seven years before Ford Motor’s founding that Henry had completed the development of his horseless carriage, which he dubbed the Quadricycle, which spurred the Detroit Automobile Company’s formation in 1899. In 1901, a company reorganization led to the formation of the Henry Ford Company. However, within a year, disputes with investors forced Ford to leave.

Henry Ford is best known for revolutionizing automobile manufacturing, but his impact reached far beyond cars. One of his lesser-known ventures helped shape how Americans cook outdoors. The story of charcoal briquettes begins not at a grill, but in Michigan’s forests.

Table of Contents

How Did Henry Ford Come to Manufacture Charcoal?

Ford founded a whole new company and immediately began producing the Model A at the Mack Avenue Assembly in Detroit. This model proved profitable, and for the next twenty years, a succession of models would be developed, culminating in the Model T, which would sell over 15 million vehicles.

At that time, automobiles were crafted from about 100 board feet of wood each. Finished wood could be found in the steering wheel, dashboard, chassis, and wheels. Wood consumption was huge. Each production day, one million board feet a day was used to manufacture the popular Model T’s, whose chassis was made mostly of wood.

Wood Waste and Ford’s Efficiency Problem

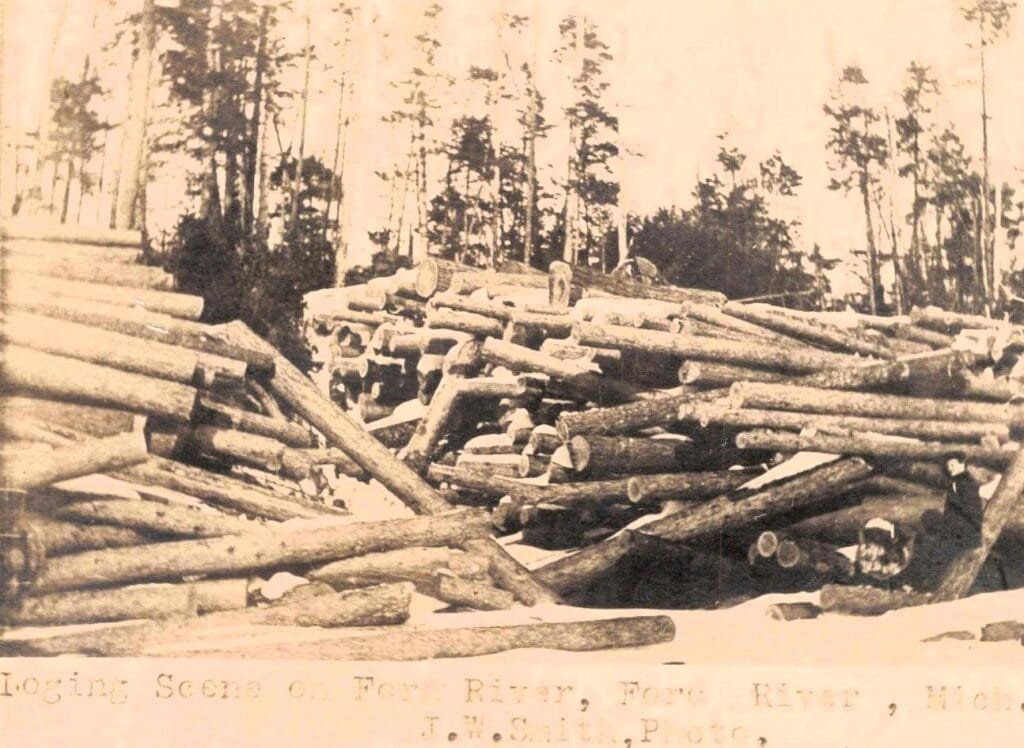

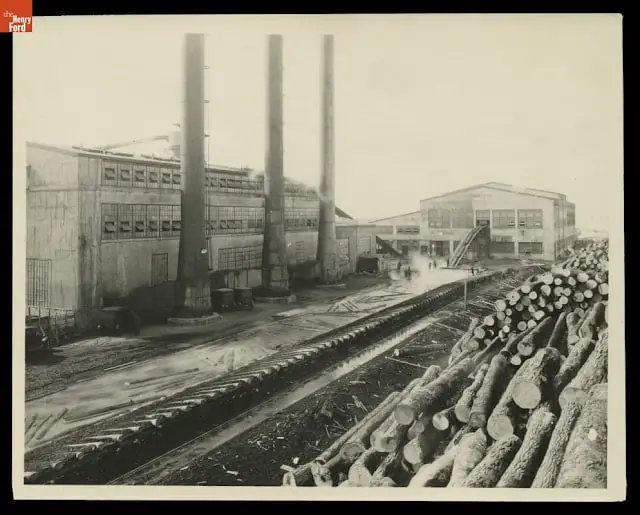

By the early 1900s, Henry Ford controlled vast timber holdings in Michigan’s Upper Peninsula. His sawmills supplied wood for vehicle frames, floorboards, and shipping crates. The operations also produced large volumes of scrap wood, sawdust, and offcuts.

Ford disliked waste. He believed every byproduct of manufacturing should be reused if possible. The challenge was finding a profitable use for the leftover wood that piled up at his mills near Iron Mountain.

The Village Industry Experiment

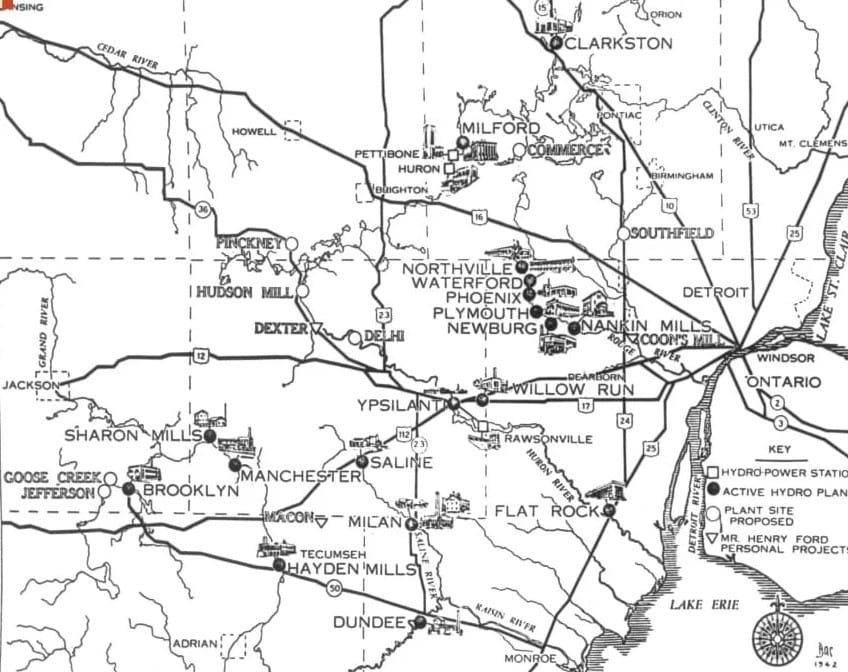

Ford, ever the innovator in minimizing waste, sought solutions to avoid depending on suppliers for components that made up his marvelous machines, including milled wood. During this period, Ford was also undertaking a massive effort to bring small-scale manufacturing to rural areas. His Village Industry experiment sought to reduce the reliance on large centralized factories. Ford was also concerned about the reliance on fossil fuels. He saw it as a potential threat to national security and to the Ford enterprise. The innovator’s interest in producing Henry Ford Charcoal stemmed from that same mindset.

Ford’s Upper Peninsula Operations

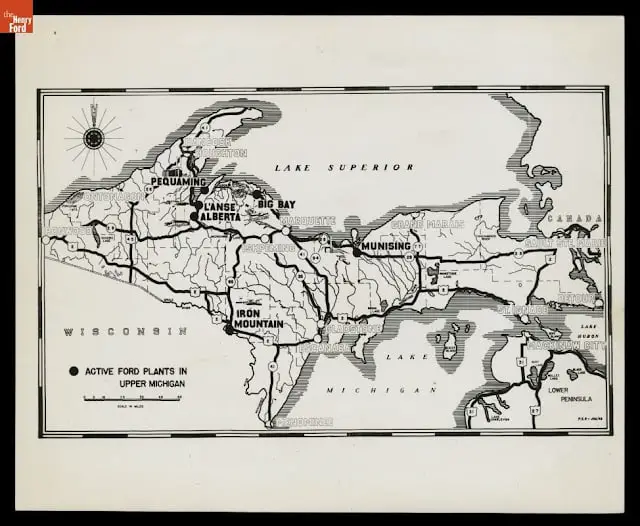

After camping and exploration trips in northern Michigan, Ford focused on making its own wood components. He reached out to his cousin’s husband, Edward Kingsford, who is operating a Ford dealership in the remote mining and lumbering town of Iron Mountain in Michigan’s Upper Peninsula. Ford wanted to purchase forest land for lumber products at Ford Motor, a true vertical-integration play. Kingsford found and purchased 313,000 acres for the operation. Sawmills were built at Pequaming, L’Anse, and Alberta. Iron Mountain was one of the largest operations, as it included an extensive sawmill and a hydroelectric plant. Kingsford became the Vice President of its operations.

While not considered one of the 20 Ford Village Industry sites, Iron Mountain’s operations shared many aspects of the rural sites. Most notable is the use of locally created power utilized to run the plant.

Lumber and Milling Operations at Ford Motor in Iron Mountain

The operations in Iron Mountain, besides milling wood, also included distilled scrap wood into chemicals for downstate plant operations, paint production, and antifreeze. The tons of sawdust and scape wood from the lumber mill and production process were collected, dried, and burned in special ovens. The resulting charred wood was crushed, mixed with potato starch, and compressed into usable briquettes for heating, cooking, and smoking meats and fish.

At its height, the plant produced 100 tons of charcoal briquettes a day. However, this amount exceeded what was needed in northern Michigan. Soon, the charcoal briquets were packed, branded, and shipped to their dealerships, who sold the charcoal across the country. Ford was so pleased with this innovative product that during Chicago’s 1933-34 Century of Progress Exposition, Ford included the packaged charcoal in the exhibit. “Picnic Kits” with Ford charcoal and portable grills were sold to promote leisure motoring, and picnicking soon began appearing for sale in Ford dealerships, and a whole new industry was born.

The Beginning of Backyard BBQ

Ford died in 1947, and the company was taken over by his grandson, Henry Ford II. The grandson, known as the Deuce, worked to phase out the Village Industries and Ford Charcoal Briquette Company at Iron Mountain.

Evolution into Kingsford Charcoal

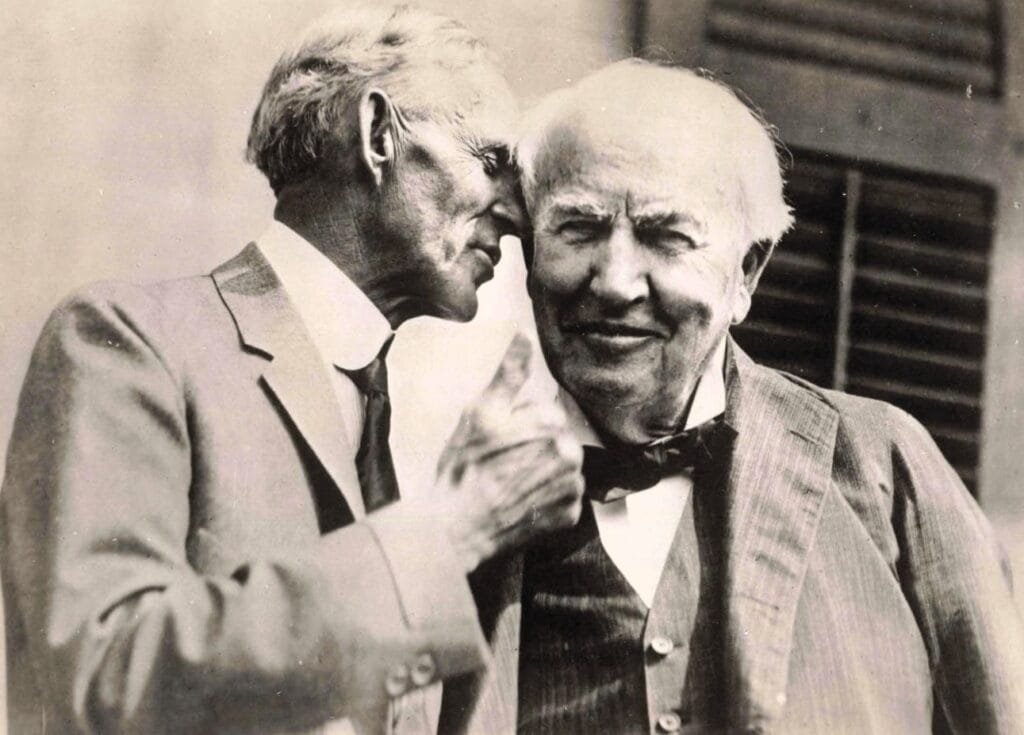

In the early 1920s, Ford’s sawmill at Iron Mountain, Michigan, processed scrap wood into fuel. A chemist developed the briquette process, and inventor Thomas Edison designed a dedicated plant. Ford marketed charcoal under the Ford Charcoal name, later sold, and rebranded in 1951 as Kingsford Charcoal, a leading U.S. charcoal brand.

Ford sold the wood-chemical operation to local businessmen, who changed the company’s name to honor its founder. The Kingsford Chemical Company was founded in 1951. Kingsford Charcoal remains the largest producer of charcoal briquets in the world.

In a way, Henry Ford was responsible for today’s popularity of backyard charcoal grilling, which is the same type.

Frequently Asked Questions About Ford Charcoal

Who invented charcoal briquettes?

Charcoal briquettes were developed in the early 1920s using wood waste from Ford Motor Company sawmills. The process refined charcoal into uniform blocks that burned evenly and consistently.

Why is Kingsford charcoal named Kingsford?

The brand was named after Edward Kingsford, a Ford executive and cousin of Henry Ford, who helped manage the early charcoal operations.

Where was Ford charcoal made?

Early charcoal production took place near Iron Mountain, Michigan, close to Ford’s Upper Peninsula sawmills.

Was charcoal part of Henry Ford’s automobile business?

Indirectly. Charcoal allowed Ford to reuse scrap wood from car manufacturing, reducing waste and creating a new consumer product.

Sources

- Ford Charcoal Briquets

- Kingford History

- All images from the Collections of The Henry Ford. Gift of Ford Motor Company.

Related Reading Henry Ford Charcoal

- Indian Trails of Michigan’s Thumb

- Saginaw Trail Today – A Photo Journey

- Michigan Indian Tribal Wars and Sebewaing’s Giant Oak

- Charity Island Dinner Cruises Begin at Caseville

- The Comfy and Rustic Cabins of the Porcupine Mountains

Great article, Michaela! They have a lot of info and old photographs about this at the WWI Glider & Military Museum in Iron Mountain as well if anyone is interested in learning more.